Twenty-eight years ago, the Internet took over the world by storm and turned it into the global village we know today.

Enter the Internet of Things, and there are more sentient objects in that village—8.4 billion as per Gartner. Everything from industrial pumps and wind turbines to self-driving cars and household appliances now shares the digital space with us.

By 2020, their number is set to touch 20 billion.

Advances in wireless communication, low-power sensors, and microcontrollers have meant that just about anything can be connected to the Internet and monitored from a distance. Together, these technologies have set in motion innovations across sectors and countries.

To illustrate, the city of Barcelona uses sensor-fed data on rain and humidity to optimally irrigate parks, saving $555,000 every year. In the industrial suburb of Louisville, Kentucky, where an alarming 12% of the residents are asthmatics, a pilot project that monitored air quality and gave public alerts helped cut down inhaler use by over 80%.

At the frontier of innovations are various industries. In retail, insurance, and manufacturing, insights yielded by sensor data are helping to address existing blind spots and optimize operations.

How Sensors Work

Any discussion on sensors invariably attracts a parallel between them and human sensory organs, which is not entirely misplaced. The human body is, after all, a grand feat of engineering. Music, movies, and cuisine are gifts of our extraordinary sensory capabilities.

Just as the human sensory organs allow sound, light, temperature, and other external stimuli to be perceived, sensors embedded in everyday objects allow them to sense changes in their immediate environment. The sensors relay this information to a software platform—comparable to the central nervous system in the human body—where it is further drilled and analyzed, and turned into actionable insights.

Key Considerations During Sensor Selection

There are many sensors, each best suited for certain applications and conditions. Their selection can be fraught with difficulty, given their variety, but here are some key points to be aware of:

- Application Requirements: You need to know your application to find a compatible fit. What does it have to sense? Is it the presence (or absence) of an object? Position? Displacement? What is the target object made of? What is its size or speed?

- Operating Environment: What is the ambient temperature? Is there any noise? Are there any vibrating parts that could interfere with sensor performance?

- Sensor Cost: Some sensors are cost-prohibitive. The device, its installation, and maintenance cost money, so it’s important to check how a sensor fares in these areas.

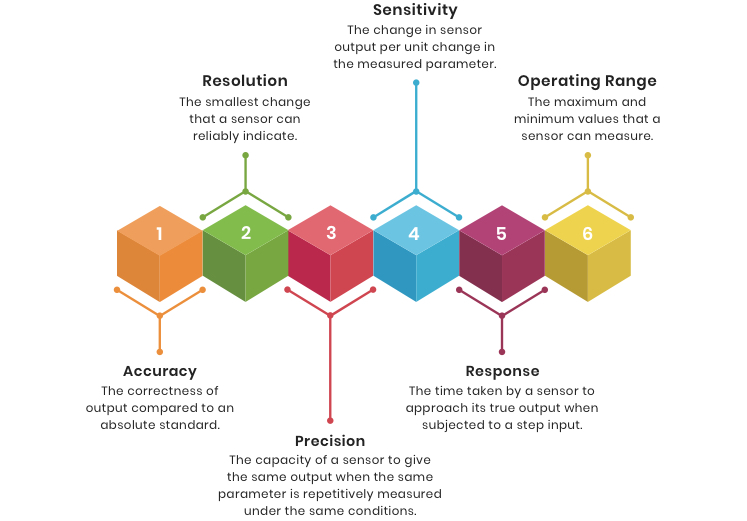

- Performance Requirements: Sensors vary widely in their performance. Some key criteria include the sensing range, accuracy, and response time. Refer image below.

Sensor Classification

Sensors fall into certain distinguishable categories, some of which are described below.

- Analog and Digital Sensors: In analog sensors, processing is continuous; that is, the output changes as soon as the input changes. In digital sensors, when the input changes, there is a delay in the change in output, which is determined by the sensor’s sampling frequency.

- Active and Passive Sensors: Active sensors require an additional power source or excitation voltage. In passive sensors, the power is provided by the measured signal itself.

- Contact and Non-Contact Sensors: Some sensors, such as strain gauges, need physical contact to sense the stimulus, while others, such as infrared thermometers, don’t require physical contact.

- Absolute and Relative Sensors: Sensors (for example, a thermistor) can provide the absolute measure of a stimulus or a measure in relation to a reference.

Sensors Classified by Detection Capabilities

Temperature Sensors

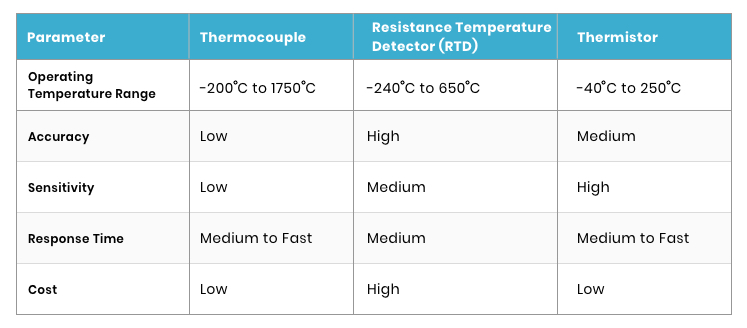

Temperature sensors are used to monitor and control the temperature in industrial settings as well as prevent machine failure due to overheating. They vary in their operating temperature range, accuracy, sensitivity, response time, and cost.

- Thermocouple: This is the most versatile temperature sensor around. It is capable of detecting a wide temperature range with greater accuracy and is therefore widely used. It consists of two dissimilar conductors connected or welded together. From the voltage difference between the two conductors, the reference temperature is derived.

- Resistance Temperature Detectors (RTD): Accuracy, stability, and repeatability make RTDs unique among temperature sensors. Temperature is measured by correlating the resistance value of the coiled wire or the resistor with its corresponding temperature.

- Thermistors: High sensitivity and high resistance distinguish thermistors from other temperature sensors. However, thermistors have a limited operating range compared to others (see table below).

Comparison of temperature sensors

Pressure Sensors

Pressure sensors help measure the pressure of liquids and gases in absolute terms or in reference to atmospheric pressure. They are also used to sense flow rates and water levels. Since they are used for a wide range of applications, their design also varies widely.

Flowmeters

Flowmeters are sensors that measure the discharge of a fluid through a pipe at a given time. The major types include differential pressure flowmeter, displacement flowmeter, open channel flowmeter, and mass flowmeter. The choice is based, among others, on the type of fluid, its temperature, viscosity, type of flow, and size of the pipe.

Accelerometers

These are electromagnetic devices that are used to measure static or dynamic acceleration. Static devices help detect the angle at which a device is tilted in relation to the earth and dynamic devices help analyze how a device is moving or vibrating. The right choice of an accelerometer depends on the axes to be measured, the variable capacitance, frequency response, and type of interface.

Beacons

A beacon is a short-range sensor that can signal its location to Bluetooth devices within its range. The strength of the signal helps determine the position of the beacon relative to the receiving device. This context awareness, powered by Bluetooth Low Energy protocol, is useful in many scenarios, such as in retail, where location-aware targeted advertisements are used to boost sales.

Proximity Sensors

Proximity sensors sense the presence of objects by analyzing electromagnetic fields, light, or sound. There are different kinds of proximity sensors – inductive, capacitive, photoelectric, ultrasonic, magnetic, and so. The choice depends on the type of object to be sensed, size, speed, and so on. Sensor specifications to be considered include sensing range and frequency.

Infrared Sensors

Infrared sensors pick up changes in their environment by emitting or detecting infrared radiation. A burglar alarm, for instance, can make use of an infrared sensor to pick up the presence of an intruder. Quantum infrared sensors have higher detection capabilities and response times than thermal infrared sensors.

Power Considerations

Figuring out the requirements and constraints is half the battle; the other half is choosing an efficient power source. There are three major power sources: batteries, energy harvesting devices, and capacitors.

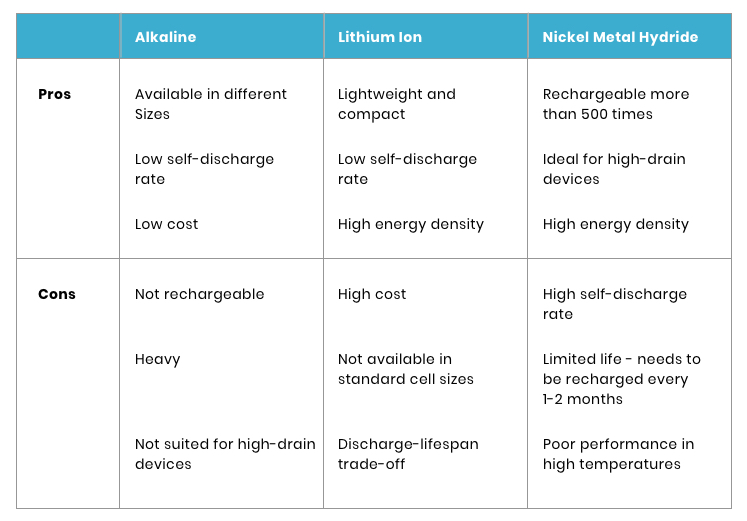

Batteries

Batteries are a major power source for portable devices and where wired networks are impractical. There are three main types: alkaline, lithium, and nickel metal hydride batteries.

Energy Harvesting Devices

Replacing batteries or undertaking their maintenance every few years can be a huge drain on any project, especially where there are hundreds of thousands of devices involved. Energy harvesting technologies are a breakthrough solution for low-power devices. These help harvest energy from light, heat, and vibration. Solar cells, thermoelectric harvesters, and piezoelectric transducers are some of the commonly used energy harvesting devices. However, their use is constrained by physical and environmental conditions.

Capacitors

Capacitors are electronic components that can store energy as an electric charge. The larger the surface of the plate and the better the insulator, the higher the amount of energy stored. Capacitors can be used as an alternative to batteries. They are often used in conjunction with energy harvesting devices. The power harvested is stored in capacitors and used as and when the IoT devices require it.