In our previous posts, we discussed sensors and wireless communications—the two components that underpin the Internet of Things technology. Our current post looks at how these technologies take effect in real life and help make a difference to operations. Two of these cases deal with real-time location systems (RTLS) implemented in healthcare and logistics and the other with condition monitoring in wind farms.

1. Medical Device Tracking

Every year, hospitals lose hundreds of thousands of dollars by way of missing or stolen equipment. In addition to that, hospital staff lose several hours per day looking for missing items. Take the case of IV pumps. Typically, large hospitals have hundreds of these, yet locating an idle one on demand can be time-consuming. An asset tracking solution backed by the Internet of Things technologies can bring real-time visibility to hospital assets and make their discovery faster.

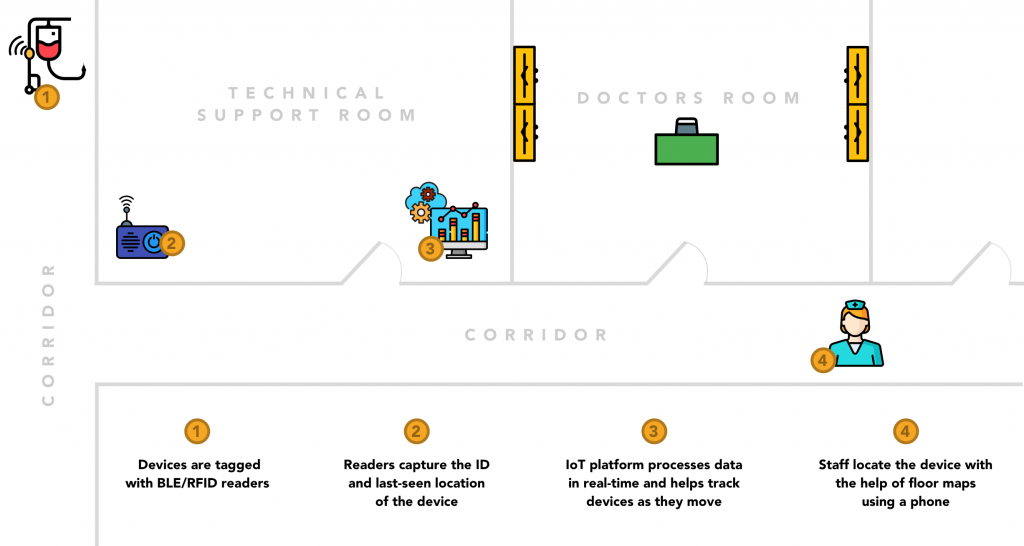

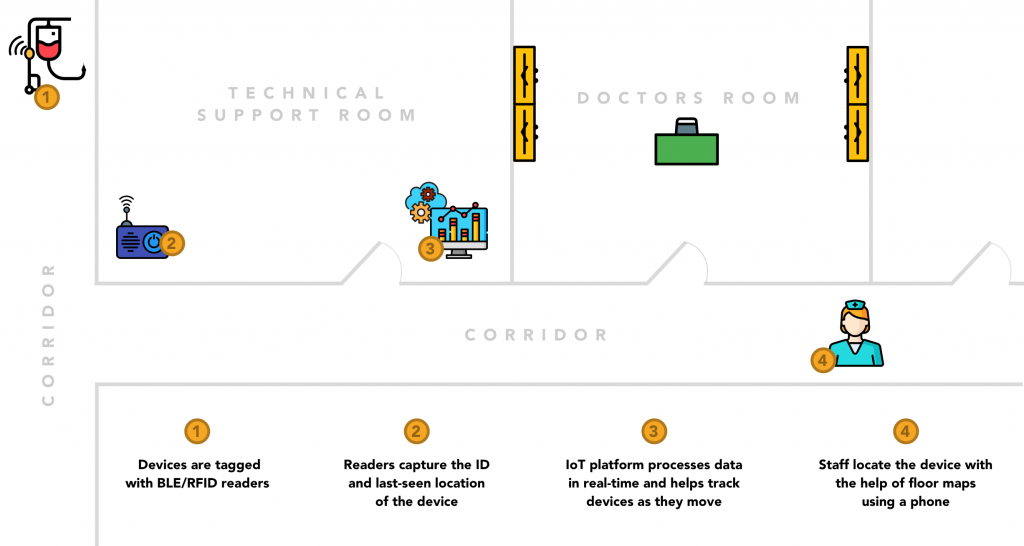

In an IoT-assisted hospital asset tracking system, BLE- or RFID-enabled tags with unique IDs are attached to each device. BLE/RFID readers are deployed in different parts of the hospital to communicate with these tags. In the case of RFID, readers send interrogatory signals over the system’s frequency and the tags on the devices respond by relaying their unique ID and thereby their last-seen location and movement. In the case of BLE, the signals are sent continuously. Based on the signal strength of BLE and WiFi location, accuracy can be improved. The system computes the position of each tagged asset through trilateration.

The device location information is transmitted from the readers to a cloud-based IoT platform over IP network. An analytical engine, the fourth component in this IoT-enabled asset tracking system, processes the data in real time, tracking the current location of each device as it moves from one room, ward, or floor to another. Clinicians can access this data on their mobiles as floor plan maps, helping them quickly identify the current location and minimize patient waiting time.

[caption id="attachment_18262" align="aligncenter" width="648"]

Medical device tracking in hospitals[/caption]

The solution can secure devices from theft using geofencing technology. When a device crosses its authorized limits, it generates alerts. Besides real-time actionable data, the application also provides analytical insights for asset planning, optimal positioning, utilization, and management by analyzing its movement history, idle hours, and downtime. This centralized and real-time updated system makes auditing simpler and reduces spend on new purchases. The same solution can be adapted to locate medical staff in case of emergencies and to locate patients who lose their way inside hospitals.

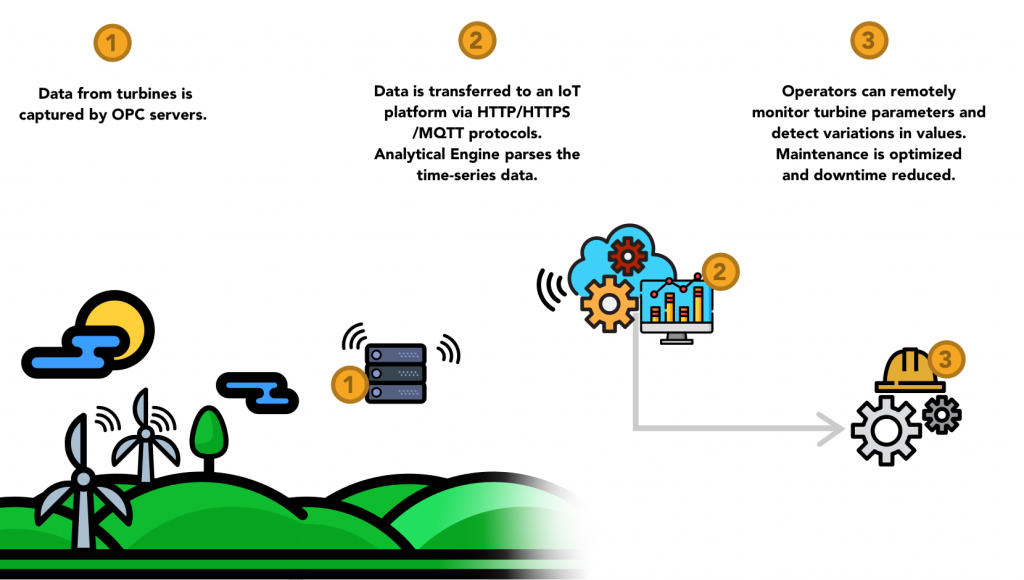

2. Remote Wind Farm Monitoring

As wind energy gains a competitive footing in most developed countries and new installations come into force in others, the stakes are high for wind energy firms. Challenges of wind variability notwithstanding, renewable energy firms can optimize operations through remote monitoring of their wind farms and turbines using IoT-assisted centralized turbine monitoring system.

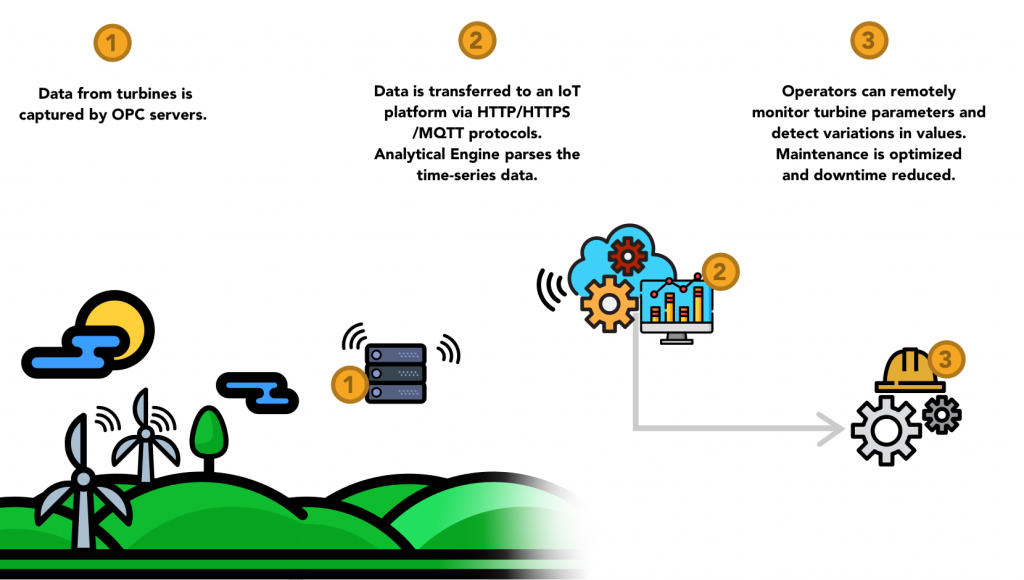

In an IoT-based remote wind turbine monitoring system, sensors attached to turbines collect data on various parameters including temperature, pressure, stress, torque, rotational speed, wind speed, wind direction, lubricant oil level, levels of vibration, the distance between components, and so on. This high-resolution data collected from OPC servers is transmitted to the cloud-based central monitoring platform via HTTP/HTTPS/MQTT protocols.

The central monitoring platform, powered by a backend analytical engine, provides the real-time status of each farm and individual status of each turbine. An intuitive interface allows users to keep track of the steady stream of data and easily detect variations in the parametric values. The system generates warnings when there are significant deviations from the standard, allowing operators to check and resolve the exact problems before they snowball into major catastrophes.

[caption id="attachment_18265" align="aligncenter" width="648"]

Remote wind farm monitoring[/caption]

A unified view of production—both current and cumulative (daily, monthly, and yearly)—gives business owners located far away from their farm a better picture of its performance and helps make decisions to minimize downtime and ramp up production. Machine learning algorithms trained on the data can further help predict turbine failure and enable predictive maintenance, minimizing disruptions to operations.

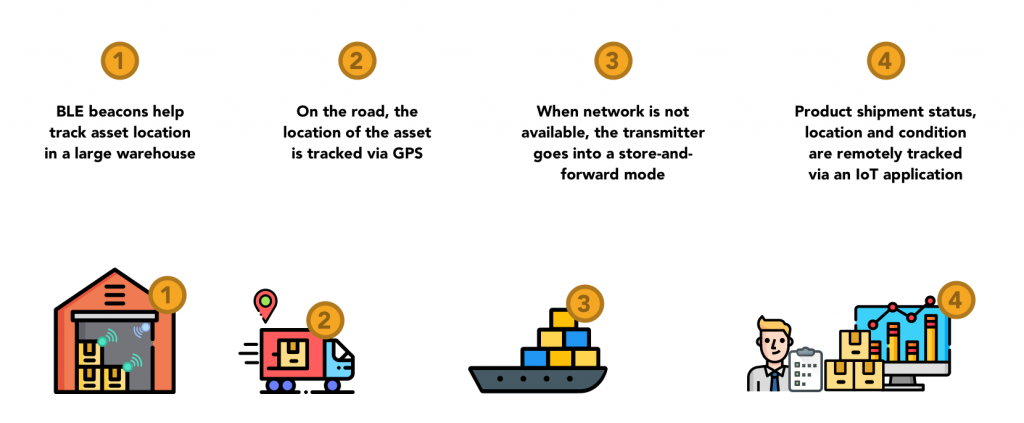

3. Asset Tracking in Logistics and Transportation

Supply chains can be circuitous; products travel via multiple systems (air, sea, rail, or road) and go through multiple handlers before they reach their destination. Tracking them was plain cumbersome if not impossible until the advent of IoT. Now companies can capture the complex timeline in real time remotely, manage their fleet and cargo more efficiently, and satisfy customer expectations of faster delivery and zero defects.

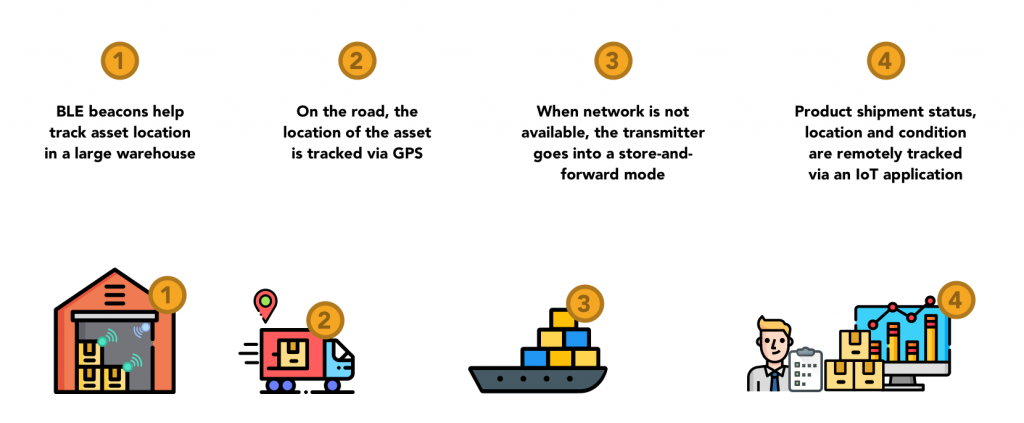

Tracking goods across the supply chain means tracking them both indoors (in a warehouse) as well as outdoors (during transit). Indoor tracking is accomplished with BLE beacons, which are fixed in clearly designated areas of the warehouse in such a way that every beacon covers a specific area on the floor map. Each beacon with its unique ID is entered in the cloud-based asset tracking system along with the area that it covers. Beacons are also placed on each item/cargo and their corresponding IDs are entered in the system. The system computes the micro location of each item with centimeter precision and helps warehouse workers accurately locate it using floor maps on their smartphone without losing time.

When an asset leaves the warehouse, a GPS receiver attached to the asset helps identify its location. The data from the sensors are relayed through a wireless network. When cellular or other wireless network is not available, the transmitter goes into a store-and-forward mode. In transcontinental shipments, SigFox Network provides location tracking, although of limited accuracy. Sensors like GPS are high-energy consuming, while SigFox positioning technology demands lesser energy. When location tracking needs to be done for a long time, power storage becomes a problem. Store-and-forward strategy that reduces the frequency of transmission is helpful in this context. Another approach is to collect location data of the ship in which container is in. The Automatic Identification System in the ship, which consists of a VHF transceiver with GPS receiver and navigation sensors broadcasts the ship’s location.

[caption id="attachment_18267" align="aligncenter" width="648"]

Asset tracking in logistics[/caption]

Manufacturers and supply chain managers can check shipment status on a centralized asset tracking system, including the amount of time spent/lost at each stage of shipping due to, say, vehicle breakdown, adverse weather conditions, or geopolitical reasons. They can make contingency plans to speed up asset flow through the rest of the supply chain or reschedule delivery without escalating costs.

In the case of perishable products, time is of the essence. Temperature and humidity sensors record the product condition during transit. Similarly, shock detection sensors help ensure the integrity of fragile and high-value products that are delivered.

Automated tracking of products throughout the supply chain significantly reduces not just the need for time-consuming manual interventions but also costs, which for logistics companies can amount to trillions of dollars. Combined with enterprise data, the IoT solution can provide comprehensive visibility into operations. This connected understanding can lead to improved inventory-related decisions, quality control, regulatory compliance, asset utilization, and maintenance management.

Medical device tracking in hospitals[/caption]

The solution can secure devices from theft using geofencing technology. When a device crosses its authorized limits, it generates alerts. Besides real-time actionable data, the application also provides analytical insights for asset planning, optimal positioning, utilization, and management by analyzing its movement history, idle hours, and downtime. This centralized and real-time updated system makes auditing simpler and reduces spend on new purchases. The same solution can be adapted to locate medical staff in case of emergencies and to locate patients who lose their way inside hospitals.

Medical device tracking in hospitals[/caption]

The solution can secure devices from theft using geofencing technology. When a device crosses its authorized limits, it generates alerts. Besides real-time actionable data, the application also provides analytical insights for asset planning, optimal positioning, utilization, and management by analyzing its movement history, idle hours, and downtime. This centralized and real-time updated system makes auditing simpler and reduces spend on new purchases. The same solution can be adapted to locate medical staff in case of emergencies and to locate patients who lose their way inside hospitals.

Remote wind farm monitoring[/caption]

A unified view of production—both current and cumulative (daily, monthly, and yearly)—gives business owners located far away from their farm a better picture of its performance and helps make decisions to minimize downtime and ramp up production. Machine learning algorithms trained on the data can further help predict turbine failure and enable predictive maintenance, minimizing disruptions to operations.

Remote wind farm monitoring[/caption]

A unified view of production—both current and cumulative (daily, monthly, and yearly)—gives business owners located far away from their farm a better picture of its performance and helps make decisions to minimize downtime and ramp up production. Machine learning algorithms trained on the data can further help predict turbine failure and enable predictive maintenance, minimizing disruptions to operations.

Asset tracking in logistics[/caption]

Manufacturers and supply chain managers can check shipment status on a centralized asset tracking system, including the amount of time spent/lost at each stage of shipping due to, say, vehicle breakdown, adverse weather conditions, or geopolitical reasons. They can make contingency plans to speed up asset flow through the rest of the supply chain or reschedule delivery without escalating costs.

In the case of perishable products, time is of the essence. Temperature and humidity sensors record the product condition during transit. Similarly, shock detection sensors help ensure the integrity of fragile and high-value products that are delivered.

Automated tracking of products throughout the supply chain significantly reduces not just the need for time-consuming manual interventions but also costs, which for logistics companies can amount to trillions of dollars. Combined with enterprise data, the IoT solution can provide comprehensive visibility into operations. This connected understanding can lead to improved inventory-related decisions, quality control, regulatory compliance, asset utilization, and maintenance management.

Asset tracking in logistics[/caption]

Manufacturers and supply chain managers can check shipment status on a centralized asset tracking system, including the amount of time spent/lost at each stage of shipping due to, say, vehicle breakdown, adverse weather conditions, or geopolitical reasons. They can make contingency plans to speed up asset flow through the rest of the supply chain or reschedule delivery without escalating costs.

In the case of perishable products, time is of the essence. Temperature and humidity sensors record the product condition during transit. Similarly, shock detection sensors help ensure the integrity of fragile and high-value products that are delivered.

Automated tracking of products throughout the supply chain significantly reduces not just the need for time-consuming manual interventions but also costs, which for logistics companies can amount to trillions of dollars. Combined with enterprise data, the IoT solution can provide comprehensive visibility into operations. This connected understanding can lead to improved inventory-related decisions, quality control, regulatory compliance, asset utilization, and maintenance management.